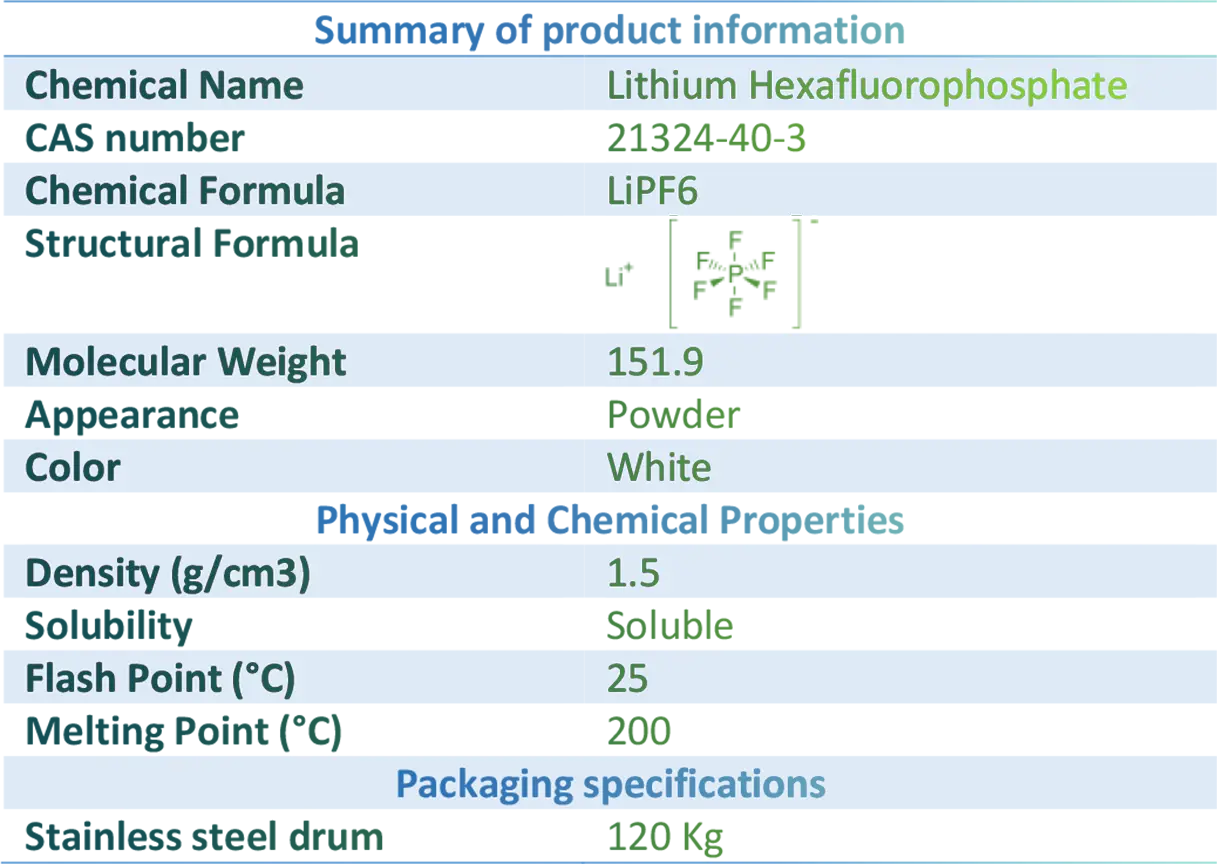

Lithium Hexafluorophosphate (LiPF6)

Lithium hexafluorophosphate (LiPF6) is the conventional salt used to produce electrolytes for lithium-ion batteries (LIBs).

LiPF6 based electrolyte is suitable for all LIB chemistries such as LCO, LMO, NMC, NCA, LFP & LMFP that are used in all sorts of applications like 3C digital devices and power tools, Electric Vehicles & Energy Storage Systems.

GFCL EV offers LiPF6 salt with good solubility, high purity and a higher degree of ion conductivity.

.webp)

Storage Unit ISO-Drums

.webp)

.webp)

.webp)